Discover why professional buyer should prioritize aftermarket requirements when sending a RFQ for production equipment and ensure long-term success (using production equipment as an example).

Content…

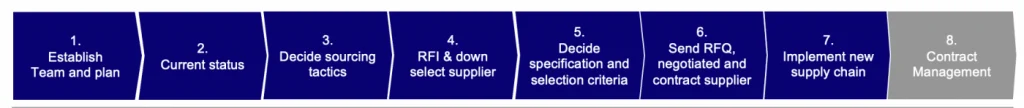

As a professional buyer, you’re well-acquainted with the Request for Quotation (RFQ) process – a critical tool for gathering pricing, delivery schedules, and product specifications from potential suppliers.

When it comes to procuring production equipment, the stakes are high, and it’s essential to make informed decisions. One often overlooked, yet crucial, factor to consider is the aftermarket demand. In this blog post, we’ll explore the importance of factoring in aftermarket demand when sending an RFQ for production equipment and how it can lead to long-term success and cost-efficiency.

What is aftermarket demand

Aftermarket demand can be divided into three main categories: consumables, spare parts, and services.

- Consumables include parts that need regular replacement to keep the equipment running smoothly, such as filters, lubricants, or cleaning materials. For instance, a high-precision CNC machine might require specific lubricants to maintain its cutting accuracy. Including these in the RFQ ensures you’re aware of their costs and frequency of replacement.

- Spare parts are essential for wear-and-tear components that may need to be replaced after a certain period, such as belts, bearings, or sensors. For example, if you’re purchasing a robotic arm for a production line, the motors or joints may wear out over time, requiring replacements. Without an understanding of these parts’ lifecycle and availability, your production could face costly downtime.

- Services encompass maintenance, repairs, and technical support. Many advanced machines come with complex electronics or mechanical systems that require periodic servicing by trained technicians. Additionally, software updates or troubleshooting support could be needed to keep the equipment running at optimal performance. For instance, a complex 3D printing machine may need specialized servicing or calibration, so it’s important to ensure the supplier can offer such services as part of the aftermarket support.

Including these aspects in the RFQ allows you to gauge the total cost of ownership and ensures that your equipment can be maintained efficiently over time. Planning for consumables, spare parts, and services helps prevent unexpected expenses and guarantees long-term equipment reliability.

Ensuring Equipment Longevity and Performance

Taking aftermarket demand into account when issuing a RFQ for production equipment helps to ensure the longevity and performance of the equipment you purchase. By selecting suppliers who prioritize the availability of spare parts, maintenance services, and upgrades, you can minimize downtime and maximize the return on your investment.

Cost-effective Maintenance and Repairs

Considering aftermarket demand also means evaluating the ease and cost of maintaining and repairing equipment. Suppliers that provide affordable and accessible replacement parts and service options are more likely to help you manage long-term costs and maintain operational efficiency.

Reducing Environmental Impact

Incorporating aftermarket demand into your RFQ process also promotes sustainability. By choosing suppliers who offer repair, refurbishment, and recycling services for production equipment, you can contribute to reducing waste and promoting a circular economy.

Fostering Supplier Relationships

When aftermarket demand is a priority, it encourages the development of strong, long-term relationships with suppliers. By working with vendors who are committed to providing ongoing support and services for your production equipment, you can develop partnerships that benefit your business for years to come.

Adaptability and Scalability

As your business grows and evolves, the aftermarket support for your production equipment becomes even more critical. Prioritizing aftermarket demand in your RFQ process ensures that your chosen supplier can accommodate your changing needs, providing equipment upgrades and modifications as required.

Conclusion: Buyer should prioritize aftermarket demand

Taking aftermarket demand into account when sending an RFQ for production equipment is vital for professional buyers. By prioritizing factors like equipment longevity, cost-effective maintenance, environmental impact, supplier relationships, and adaptability, you can make informed decisions that lead to long-term success and cost-efficiency. Don’t overlook this crucial aspect – make aftermarket demand a key consideration in your next RFQ for production equipment.

Learn more about RFQ documents in the basic level course; RFQ Template.

Note: Illustration to blogpost “Buyer should prioritize aftermarket demand” was created by Chat GPT on Sept 8, 2024.

Information about LHTS Online Procurement courses in Swedish.