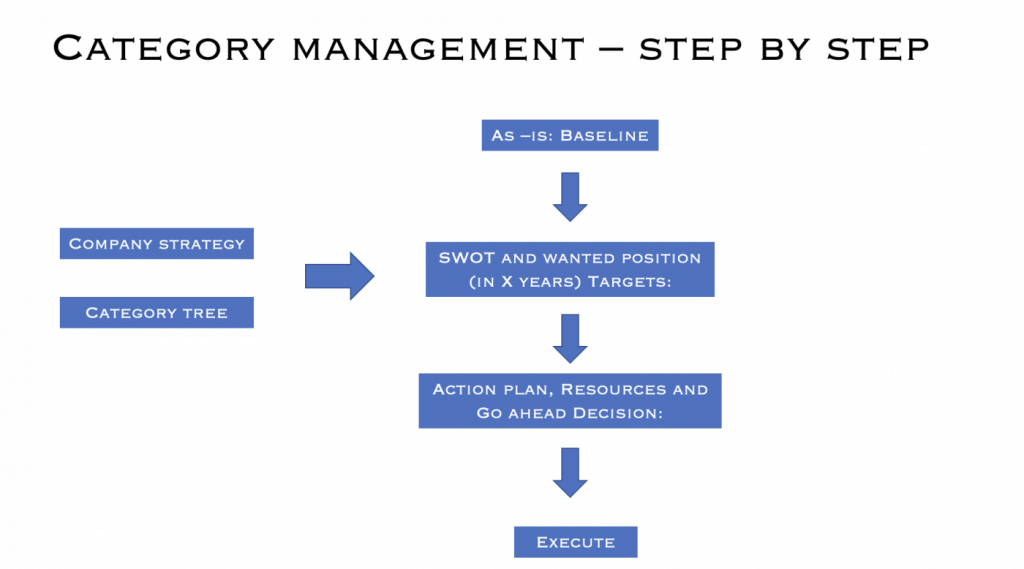

Category Strategy for Small Machined Parts in the Scandinavian market outlines the procurement approach. The strategy includes a spend analysis, a wanted position, a market analysis, a SWOT analysis, and an action plan. The ultimate goal is to optimize cost, quality, and supply chain sustainability while mitigating risks associated with market fluctuations and supplier performance.

Content…

Small Machined Parts: An Overview

Small machined parts are precision-engineered components that are typically used in a wide range of industries, including aerospace, automotive, electronics, medical devices, and manufacturing. These parts are manufactured using various machining processes, such as turning, milling, and grinding, to achieve the desired shape, size, and surface finish. Small machined parts play a crucial role in the assembly and functioning of complex machinery and equipment, contributing to the overall performance, durability, and reliability of the systems they are integrated into.

Types of Small Machined Parts

- Precision Turned Parts: These components are created using a turning process, where a cutting tool removes material from a workpiece that is rotating around an axis. Common types of precision turned parts include screws, bolts, shafts, and pins.

- Milled Components: Milled components are produced using a milling process, which involves a rotating cutting tool that moves along multiple axes to remove material from the workpiece. Examples of milled components include brackets, housings, and custom-shaped parts.

- Sheet Metal Parts: These components are made from thin sheets of metal that are cut, bent, and shaped using various processes, such as laser cutting, punching, and stamping. Common sheet metal parts include enclosures, brackets, and chassis.

- Miscellaneous: This category includes other small machined parts that do not fall into the aforementioned categories but are still integral to the functioning of machinery and equipment. Examples include gears, bushings, and fittings.

Materials Used in Small Machined Parts

Small machined parts can be made from a variety of materials, depending on the requirements of the specific application. Some common materials used in the manufacturing of these components include:

- Metals: Steel, aluminum, brass, bronze, copper, and various alloys are commonly used in the production of small machined parts due to their strength, durability, and resistance to wear and corrosion.

- Plastics: High-performance engineering plastics, such as nylon, PEEK, and acrylic, are often utilized for their lightweight, corrosion-resistant, and low-friction properties.

- Composites: Composite materials, such as carbon fiber and fiberglass, offer unique properties, including high strength-to-weight ratios and resistance to temperature fluctuations, making them suitable for demanding applications.

Spend Analysis

- Total Spend: The total annual spend on small machined parts is estimated at €X million.

- Supplier Spend Distribution: The top five suppliers account for 65% of the total spend, with the remaining 35% distributed among various small and regional suppliers.

- Spend by Product Category: The major product categories and their respective spend percentages are: precision turned parts (40%), milled components (30%), sheet metal parts (20%), and miscellaneous (10%).

Wanted Position in a Category Strategy for Small Machined Parts

- Cost Optimization: Achieve cost savings of 10-15% through strategic sourcing, leveraging volume discounts, and consolidating suppliers.

- Quality Improvement: Ensure consistent quality across all product categories by partnering with reliable suppliers and establishing robust quality control measures.

- Supply Chain Sustainability: Promote local sourcing and implement environmentally friendly practices to reduce the environmental impact of the supply chain.

- Supplier Relationship Management: Build long-term relationships with key suppliers to ensure continuous improvement and innovation.

Market Analysis

Market Size: The Scandinavian market for small machined parts is valued at approximately €XX million, with a CAGR of X% over the last five years.

Market Trends:

a. Industry 4.0: The increasing adoption of advanced manufacturing technologies, such as automation and IoT, is transforming the small machined parts industry.

b. Sustainability: Growing awareness of environmental issues has led to increased demand for sustainable and eco-friendly manufacturing processes.

c. Customization: The rising demand for customized components is driving market growth.

Key Players: Major players in the Scandinavian small machined parts market include SKF, Sandvik, Seco Tools, and GKN Aerospace, among others.

An analysis of the market for Small Machined Parts in the Scandinavian market using Kraljic’s Matrix:

- Supply Risk: The supply risk for Small Machined Parts in the Scandinavian market is generally low to medium. While there are many suppliers of Small Machined Parts in the region, the demand for these parts can be highly specific and customized, which may require suppliers to have specialized expertise and equipment. The supply chain for Small Machined Parts is generally reliable, but disruptions in the supply chain can have a significant impact on businesses that rely on these parts.

- Profit Impact: The profit impact of Small Machined Parts on businesses is generally medium to high. These parts are often critical components of larger systems, and their quality and performance can have a direct impact on the performance of the overall system. Additionally, the customization and complexity of Small Machined Parts can result in higher costs, which can impact the profitability of businesses that require these parts.

- Volume Purchased: The volume of Small Machined Parts purchased by businesses can vary widely, depending on the size of the company and its operations. Large businesses may require a higher volume of these parts to support their operations, while smaller businesses may only require a few customized parts. However, overall, the volume of Small Machined Parts purchased in the Scandinavian market is significant due to the high demand for precision engineering and specialized manufacturing.

- Purchasing Complexity: The purchasing complexity of Small Machined Parts is generally high. These parts require specialized expertise and equipment to produce, and the customization and complexity of these parts can result in a lengthy and detailed purchasing process. Businesses may need to work closely with suppliers to ensure that the parts meet their specific requirements, which can add to the complexity of the purchasing process.

- Based on this analysis, Small Machined Parts in the Scandinavian market fall into the “Bottleneck” quadrant of Kraljic’s Matrix. This means that the supply risk is low to medium, but the profit impact and purchasing complexity are medium to high. As a result, businesses that rely on Small Machined Parts should take care to manage the purchasing of these parts carefully, focusing on factors such as quality, performance, and pricing. Additionally, businesses may want to consider developing close relationships with suppliers to ensure that they have reliable access to these critical components.

SWOT Analysis Category Strategy for Small Machined Parts

Strengths:

- Established relationships with key suppliers

- Comprehensive understanding of product requirements

- In-house expertise in procurement and supply chain management

Weaknesses:

- Fragmented supplier base leading to inefficiencies

- Limited focus on sustainability and eco-friendly manufacturing

- Inconsistent quality across product categories

Opportunities:

- Consolidation of suppliers to optimize costs

- Expansion of local sourcing initiatives

- Leveraging Industry 4.0 technologies to improve manufacturing processes

Threats:

- Fluctuations in raw material prices impacting product costs

- Intense competition from low-cost manufacturing countries

- Technological disruptions affecting traditional manufacturing processes

Action Plan Category Strategy for Small Machined Parts

- Supplier Consolidation: Evaluate and reduce the number of suppliers to a core group of strategic partners, leveraging volume discounts and improving efficiency.

- Quality Control: Implement robust quality control measures, including supplier audits and regular product inspections.

- Supply Chain Sustainability: Encourage local sourcing, prioritize eco-friendly manufacturing practices, and promote environmental responsibility within the supply chain.

- Supplier Relationship Management: Establish long-term relationships with key suppliers, focusing on collaboration, innovation, and continuous improvement.

- Technology Adoption: Utilize Industry 4.0 technologies, such as automation and IoT, to streamline procurement processes and improve data-driven decision-making.

In conclusion, small machined parts are essential components in various industries, where they contribute to the proper functioning and performance of complex machinery and equipment. These precision-engineered parts are manufactured using a range of machining processes and can be made from different materials, depending on the application requirements. Their importance in maintaining the efficiency and reliability of systems cannot be understated, making them a vital aspect of modern engineering and manufacturing. The Category Strategy for Small Machined Parts provides a comprehensive approach to optimize procurement for the small machined parts category in the Scandinavian market. By focusing on cost optimization, quality improvement, supply chain sustainability, and supplier relationship management, the organization can achieve its strategic objectives.

Learn more about Category Management. This advanced course will help you with the first steps when implementing Category Management. The course includes a broader explanation of Category management, the content of a first version of a Category strategy and key finding (checklists).

Hope you have found inspirations to your Category Strategy for Small Machined Parts.

Note: Illustration to blogpost “Category Strategy for Small Machined Parts” was created by CHAT-GPT on May 10, 2023.

At Utbildning Inköp you can learn in Swedish about LHTS’ courses.