In today’s fast-paced and competitive business environment, companies are increasingly relying on suppliers to not only provide raw materials and components, but also to actively participate in the design and development process of products and services. Nurturing valuable supplier relationships has become a competitive edge.

Suppliers have gradually built a deep understanding of their customers’ processes, including the way they write specifications, use CAD programs, and adhere to industry standards. Given the significant investments involved in developing these relationships, it is crucial for companies to effectively manage, and potentially develop, their strategic suppliers.

In this blog post, we will explore the importance of nurturing valuable supplier relationships and discuss some strategies for fostering successful co-design partnerships. Could even Procurement departments take the lead in product development related to non-core competencies/capabilities when standard parts/services is not enough?

Content…

Recognizing the Value of Strategic Suppliers

Before diving into the management aspect, it is essential to understand the role of strategic suppliers in the design and development process. These suppliers possess the knowledge and expertise to create innovative solutions, often resulting in improved products, reduced costs, and shortened time-to-market. By acknowledging their value, companies can better appreciate the need for ongoing investment in these relationships.

Building Trust and Collaboration

A foundation of trust and open communication is key to any successful partnership. Companies should strive to foster a collaborative environment where suppliers feel comfortable sharing ideas, concerns, and potential improvements. Encouraging suppliers to participate in decision-making processes and demonstrating appreciation for their contributions can go a long way in nurturing trust and collaboration.

Aligning Objectives and Goals

For a co-design partnership to thrive, it is crucial that both parties share a common vision and are aligned in terms of strategic objectives. By involving suppliers in the early stages of the product development process, companies can ensure that the supplier’s capabilities and expertise are fully leveraged. This alignment also allows for greater transparency and understanding of each party’s expectations, further solidifying the relationship.

Co-investing in Process Development

To maintain a competitive edge, companies should actively invest in the development of their strategic suppliers and the common processes (process interfaces). This can include providing training, sharing best practices, and offering resources to help suppliers enhance their capabilities. By investing in supplier development, companies can benefit from improved performance, reduced risk, and a stronger overall partnership.

When seeking co-design partners

When seeking co-design partners, it is essential to understand the different types of organizations available and the unique capabilities they bring to the table. In this blog post, we will explore three distinct types of co-design partners (there are of course multiple others): engineering firms with design capability only, engineering firms with capability to source, and manufacturing companies with design capabilities. By understanding the strengths and limitations of each type, you can make informed decisions when selecting the ideal partner for your specific needs.

Engineering Firms with Design Capability Only

These firms specialize in providing design and engineering services without taking responsibility for sourcing components or manufacturing the end product. Their primary focus is on developing innovative designs and providing technical expertise to address complex engineering challenges.

Strengths:

- High level of design and engineering expertise

- Access to specialized tools and software

- Ability to tackle complex design challenges

Limitations:

- No direct involvement in sourcing or manufacturing processes

- Potential for additional coordination efforts with other partners

Engineering Firms with Capability to Source

In addition to design expertise, these firms also possess the capability to source the required components and materials for a project. This can save time and effort by streamlining the design and procurement processes.

Strengths:

- Comprehensive design and engineering services

- Expertise in sourcing components and materials

- Potential for cost savings through strategic sourcing

Limitations:

- Limited control over manufacturing processes

- May require collaboration with additional partners for manufacturing

Manufacturing Companies with Design Capabilities

These companies specialize in the actual production of goods but also possess in-house design capabilities. This integration of design and manufacturing expertise can result in a smoother and more efficient development process, as well as enhanced quality control.

Strengths:

- In-house design expertise combined with manufacturing capabilities

- Streamlined product development process

- Enhanced quality control through close collaboration between design and manufacturing teams

Limitations:

- Potential for limited design and engineering expertise compared to specialized engineering firms

- May require coordination with external design partners for more complex projects

Could procurement be responsible for product development?

Yes, certainly for non core products. Understanding the distinction between core and non-core competencies and capabilities is essential for businesses striving to achieve a competitive edge in their industry.

Core Competencies and Capabilities

Core competencies are the unique combination of skills, knowledge, and resources that differentiate a company from its competitors and provide a competitive advantage. These competencies are often deeply ingrained within the organization and enable it to deliver superior value to customers. Core capabilities are the processes or systems through which a company leverages its core competencies to create customer value and achieve strategic objectives. Examples of core competencies and capabilities include technological expertise, exceptional customer service, or a highly efficient supply chain.

Non-Core Competencies and Capabilities

Non-core competencies and capabilities, on the other hand, are the skills, knowledge, and resources that are not central to a company’s competitive advantage. While they may still contribute to the overall functioning and success of the organization, they do not differentiate the company in the marketplace. Non-core capabilities are the processes and systems that support non-core competencies. Examples of non-core competencies and capabilities include basic administrative functions, routine maintenance, or standard marketing practices.

The Importance of Identifying Core and Non-Core Competencies and Capabilities

Recognizing the distinction between core and non-core competencies and capabilities is crucial for various reasons:

Resource Allocation: By identifying core competencies and capabilities, businesses can prioritize investments in areas that drive their competitive advantage while optimizing or outsourcing non-core activities to reduce costs and improve efficiency. By nurturing Valuable Supplier Relationships access to non-core resources can be established

Strategic Focus: Understanding core competencies and capabilities enables companies to focus on their unique strengths and build strategies that leverage these competitive advantages.

Continuous Improvement: Identifying core competencies and capabilities can help organizations establish clear objectives and performance indicators, fostering a culture of continuous improvement and innovation in key areas.

Outsourcing Product development Recognizing non-core competencies and capabilities can guide businesses in making informed outsourcing decisions, allowing them to allocate resources more effectively and focus on your core strengths.

Conclusion

In an era where co-design partnerships are becoming increasingly important, managing and nurturing valuable supplier relationships is essential for companies looking to stay ahead of the competition. By building trust and collaboration, aligning objectives and goals and investing in supplier development, companies can effectively manage their strategic suppliers and create long-lasting, mutually beneficial partnerships. Remember, the success of your company is often linked to the strength of your supplier relationships. Invest in these relationships, and you’ll be investing in the future success of your business.

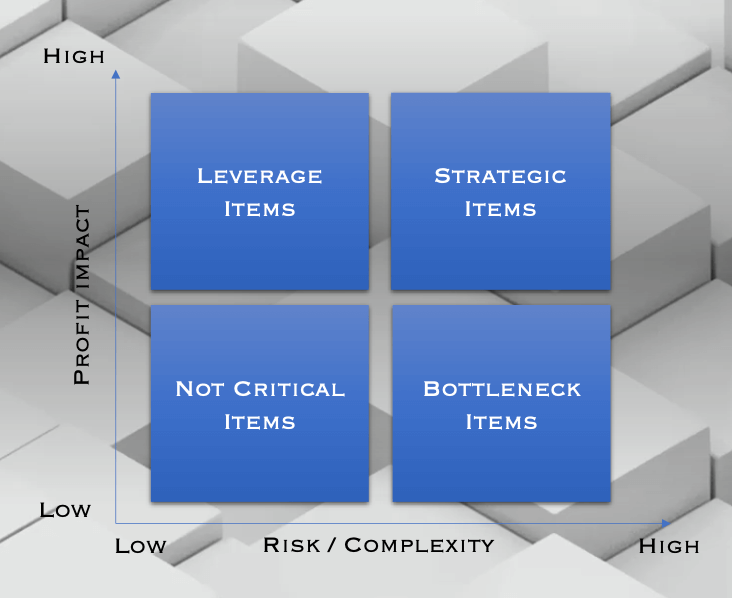

Learn more about different supplier strategies in Rogers’ course about Kraljic and Portfolio analyses.

When selecting a co-design partner, it is important to carefully consider the unique capabilities of each type of organization. Engineering firms with design capability only can offer unparalleled design expertise, while engineering firms with the capability to source can streamline the procurement process. Manufacturing companies with design capabilities offer a comprehensive solution by combining design and manufacturing expertise under one roof. By understanding the strengths and limitations of each type, you can make informed decisions that align with your specific needs and foster successful co-design partnerships.

Attend the course Category Management by EFFSO and get an introduction to the concept of category management and how to build a category management program.

Understanding the difference between core and non-core competencies and capabilities is vital for businesses seeking to maintain a competitive edge in today’s dynamic market landscape. By focusing on unique strengths and effectively managing non-core activities, companies can maximize their potential for growth and success. Thereby Procurement departments can take on the responsibility to source development of non core products and services by nurturing valuable supplier relationships.

Note: Illustration to the blogpost “Nurturing Valuable Supplier Relationships: Success in Design” was created by Chat-GPT on September 8, 2024.

At Utbildning Inköp you can find information in Swedish about LHTS’ courses.